The Ancient Technology of the Synovial Joint:

Where Engineering Meets Reality

One of the most obvious displays of true technology are joints. In human engineering, a joint is a mechanical connection that allows controlled movement between parts, such as hinges in doors, ball-and-sockets in machinery, and pivots in tool. Every builder knows joints are essential: without them, machines cannot bend, rotate, or absorb stress. They are so common that we rarely notice them, yet they are at the heart of every mechanical system, from engines and robots to furniture and vehicles.

What’s consistently ignored is the fact that the human body already contains all of these designs. Hinges, pivots, saddles, and ball-and-sockets are ancient technologies built into us. And unlike their man-made counterparts, natural joints are far more advanced — lubricated, shock-absorbing, self-repairing, and designed to last for decades under constant use. Our technologies arise as manifestations of our intuitions of Natural Technology.

Our engineering borrows its terminology directly from anatomy, where the synovial joints — the freely movable joints of the body — fall into the same categories: hinge joints at the knee and elbow, ball-and-socket joints at the shoulder and hip, pivot joints in the neck, saddle joints at the thumb, plane joints in the foot, and condyloid joints at the wrist. We do not distinguish between human and man-made designs, because the engineering principles are the same.

Friction Solution

Joints, in humans and across the animal world, are not crude bone connections. The ends of bones are sculpted into precise geometries that allow smooth, stable motion. Even the slightest variation would cause dislocation or stiffness. Our bodies possess the kind of precision engineers strive for with machined parts, yet joints achieve it dynamically at the cellular level.

Precision alone is not enough. All human-made machines face friction, and human engineers counter it with oils, greases, and bearings. Even then, wear is inevitable, and parts must be serviced or replaced. Biological joints, however, solve the problem differently: they are self-lubricating. Synovial fluid reduces friction to levels lower than Teflon and is continually replenished by the surrounding membrane. Without this, cartilage would shred within days. Unlike any man-made hinge, the lubrication system is built-in and renewable.

Shock Absorbers

Everyday movements generate massive forces. Human engineers handle impact by installing shock absorbers in vehicles and machinery, but these wear out and must be replaced. Joints, by contrast, are protected by articular cartilage — an elastic, resilient tissue that cushions impact and spreads load. Cartilage absorbs energy like a spring while maintaining an ultra-smooth surface. Without it, bone would grind on bone, and motion would quickly destroy the system. No man-made shock absorber matches the longevity or self-maintaining qualities of cartilage.

Movement must be guided. Ligaments hold bones in alignment like tension cables, allowing the right degree of freedom while preventing dangerous dislocations. Tendons connect muscles to bones, translating power into precise motion. These stabilizers give joints their controlled freedom — strength without rigidity, flexibility without collapse.

The most striking difference between natural and artificial joints is self-repair. Artificial implants are static; once worn, they must be replaced. Natural joints are alive. Cartilage cells and synovial tissue constantly monitor stress, replenish lubrication, and repair microdamage. This is why joints can endure decades — billions of motion cycles — under constant load. No engineered joint even approaches this.

The Irreducible Complexity of Joints

Joints only work as complete systems. Remove one element, and the entire mechanism fails:

Bone geometry without cartilage results in grinding and destruction.

Cartilage without lubrication shreds almost instantly.

Lubrication without ligaments serves no purpose.

Ligaments without muscles leave the joint immobile.

Muscles and tendons without stabilizers cause collapse.

Repair systems without the rest have nothing to maintain.

Every part is required simultaneously. A half-joint is not a stepping-stone — it is useless. This is irreducible complexity at its clearest: the system cannot evolve gradually because partial forms offer no function.

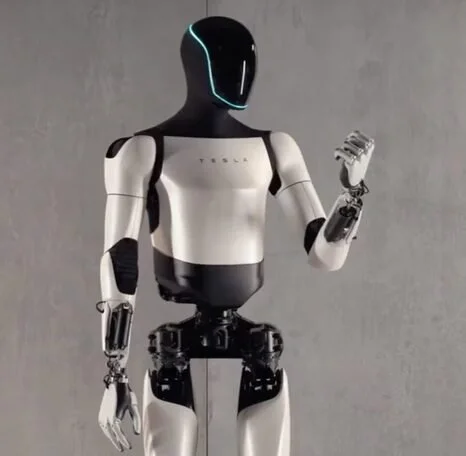

When we attempt to build robots that mimic humans, dogs, or cats, the challenge becomes obvious. Engineers spend millions designing joints, actuators, and sensors to replicate walking, running, or grasping. These projects require cutting-edge technology, yet the results still appear clunky, limited, and artificial. Every step is noisy and energy-hungry, balance is unstable, and movements lack the smooth realism of living creatures.

This comparison highlights the gap. If robotics demands our most advanced laboratories to approximate what a knee or shoulder does naturally, then the natural joint is not a simple accident of biology. It is a system of technology far beyond our own.

The contrast is clear. Our most advanced implants are crude imitations of what natural joints accomplish effortlessly. Joints embody every principle of technology, yet they surpass human engineering because they are living systems, seamlessly integrated with the rest of the body.

If you want to see more examples of how the body outpaces our best inventions, get your copy of Natural Technology: The Theory of Everything today. See what has been hidden in plain sight.

Also check out: 📖 War of Cosmogonies: uncovering the hidden history and the ideological battles that shaped the “consensus.”

If you like this content and want to be updated when new articles come out, follow me here on Facebook. And don’t forget to like and share so others can see it too.